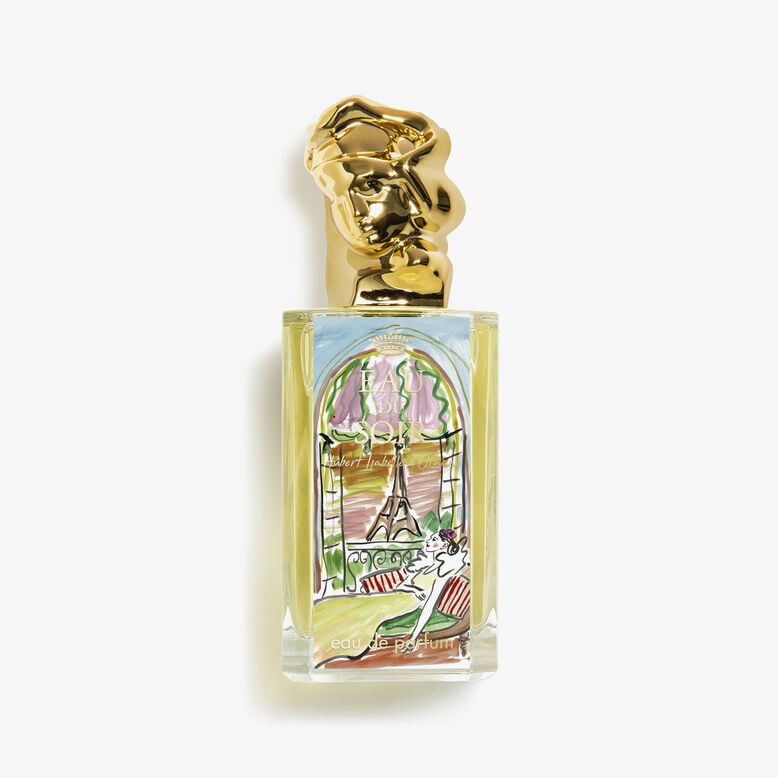

New Limited Edition

Eau du Soir Limited Edition by Luke Edward Hall

Eau du Soir - Eau de Parfum Limited Edition 100ml

Welcome to sisley-paris.com/en-INT/!

Where thoughtful giving meets timeless beauty.

Sisleÿum for Men

A three-step routine to strengthen, soothe and protect men’s skin, day after day.

Decorated by Luke Edward Hall, this exceptional gift set contains a selection of beauty essentials to take you through until Christmas.